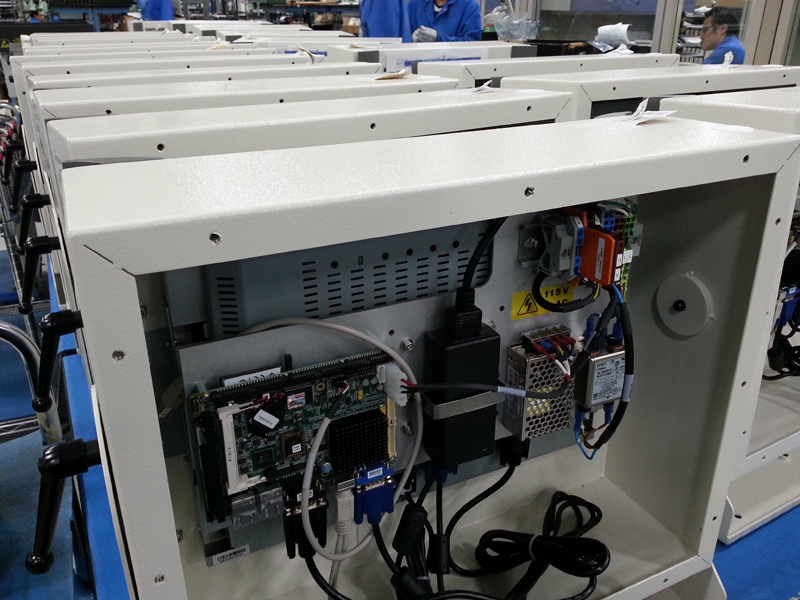

At LeeMAH Electronics, we have been manufacturing custom cable assemblies since 1971. We are proud to serve as an ISO 9001:2015 and AS9100D certified manufacturer, serving clients worldwide with a broad range of capabilities. For customers ranging from the medical, military, and instrumentation industries to transportation and pro audio, our cable assemblies combine excellent performance with cost-effectiveness. We fulfill all of our customers’ requirements, from single conductor wires to complex electronic cables and more.

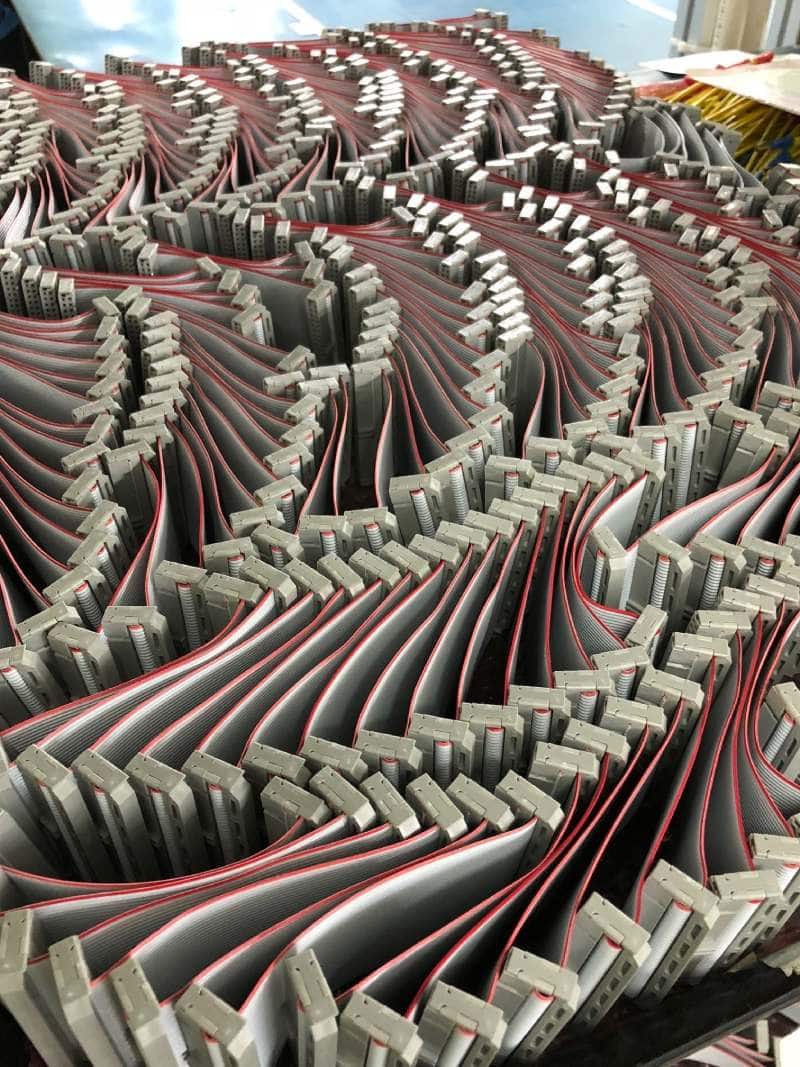

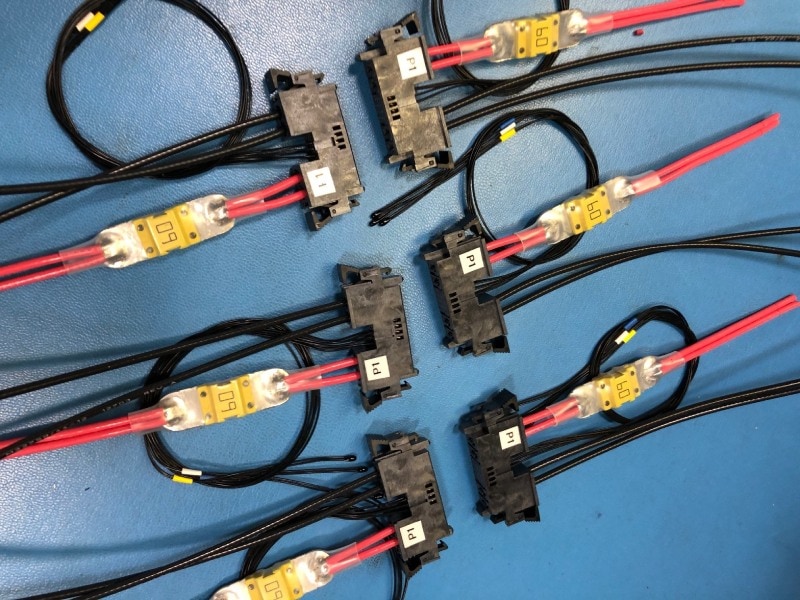

Our electronic manufacturing services cover a broad range of assemblies, including coaxial cable, semi-rigid cable, and complex harness assemblies, along with crimp, solder, and IDC connections. We maintain some of the best quality equipment in the industry, including a complete array of Cirrus logic signature testers, Schleuniger and thermal wire strippers, Eubanks wire cutters, and amp, molex, and JST terminal applicators. With this machinery, we provide a complete array of custom cable manufacturing. We offer soldering, semi-automatic and manual crimping, automated wire cutting and stripping, and marking services that include thermal printing and offset marking. Virtually every type of electric wire and cable is available for our custom assemblies, including ribbon, discrete wire, multi-conductor, and twisted pair, among others.

Quality is essential for cable assembly, and we ensure that everything we produce meets the most stringent industry standards. We provide complete in-process and final inspections using the best quality Cirrus testing equipment. Some of these include continuity, component detection, hi-pot, and crimp/pull testing. Our work regularly meets or exceeds the standards of Mil-spec, RoHS, PIC, UL, FDB, and many others.

We are proud to be one of the industry’s most trusted resources for custom cables of all coverings, insulations, thicknesses, and lengths. To learn more about our extensive assembly capabilities, please see the following table or contact us directly.

Custom Cable Assembly Highlights

| General Capabilities |

Coaxial cable assemblies Crimp, solder, and IDC connection Semi-rigid cable assemblies Complex Harness Assemblies |

| Assembly Service |

Semi-automated Assembly Prototype & NPI |

| Equipment |

Amp, Molex, and JST Terminal Applicators Cirrus Logic Signature Testers Schleuniger Wire Strippers Thermal Wire Strippers Eubanks Wire Cutter |

| Manufacturing Capabilities |

Semi-automatic & Manual Crimping Automated Wire Cutting & Stripping Marking

|

| Electric Wire and Cable Type |

Coaxial Ribbon Discrete Wire Multi-conductor Twisted Pair We work with most cable types please inquire if you don’t see your application. |

| Covering |

Braided

Heat Shrink |

| Insulation Type |

PTFE PVC Rubber We meet any of our clients insulation requirements |

| Conductor Material |

Copper Tin Copper |

| Wire and Cable Length | As per Customer Specifications |

| Wire/Cable Thickness |

Max: 0 AWG Min : 30 AWG |

| Testing |

Complete In Process and Final Inspections Utilizing Cirrus Testing Equipment

|

| Production Volume |

Low Volume to High Volume Prototype |

| Lead Time (Manufacturing) | Standard 2 weeks |

| Additional Services Provided |

Component Sourcing Engineering Potting |

Additional Information

| Industry Focus |

Communications Industrial Instrumentation Medical Devices Military / Aerospace Transportation Professional Audio |

| Industry Standards |

AS9100D / ISO-9001:2015 Certification NIST Standards MIL-STD-45662 IPC 610 & 620 Class II & III standards RoHS compliant ITAR Registered FDB Device License Certification |

| File Formats |

AutoCAD(DWG)

DXF - Drawing Exchange Format Microsoft Excel GIF - Graphics Interchange Format JPEG - Joint Photographic Experts Group PDF - Portable Document Format TIFF - Tagged Image File Format SolidWorks |